Fast search

Text search non of webshop content

Detailed Search

33 x 1,5 O-ring | NBR-70

O-ring Details

KTT Kubinszky Sealing Technology. Your professional partner | Manufacturing and trading of a wide range of O-rings, radial shaft seals, hydraulic and other seals.

Technical data

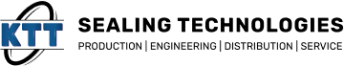

DIMENSIONING

Typical dimensions:

d1 = inner diameter

d2 = cord diameter

Rule of dimensioning: d1 x d2

Important abbreviations:

FDA – applicable in food industry (fulfillment for regulation of FDA – Food and Drug Administration)

FEP – FEP (fluoroethylene propylene) encapsulated

APPLICATION AREA

O-rings are widely used sealing elements employed in various industries to solve multiple sealing and insulating tasks. These rings are designed in an oval shape and are typically made of NBR, HNBR, EPDM rubber, neoprene (CR), fluoro-rubber (FKM, FPM, Viton), silicone (MVQ, VMQ), PTFE or other rubber-based materials. O-rings find applications in several areas, including:

Hydraulics and Pneumatics

O-rings are commonly used in hydraulic and pneumatic systems. They help eliminate fluid or gas leakage at connections, contributing to system efficiency and reliability.

Automotive and Mechanical Industry

In the automotive sector, O-rings play a crucial role in engines, transmissions, and other components. They ensure the sealing of oil and other fluids, thus enhancing the efficiency of vehicles.

Food Industry

In the food industry, O-rings are employed in applications where sealing and hygiene are critical. They are used for handling compressed air and gases and in food processing machinery. The FDA means in product name the fulfillment for regulation of Food and Drug Administration and this products are surely applicable in food industry.

Electronics

O-rings are also used in the manufacturing of electronic devices and equipment. These sealing elements help prevent dust, water, and other contaminants from entering around electronic components.

Oil and Gas Industry

O-rings have a significant role in the oil and gas sector during drilling and transportation processes. They prevent oil and gas leakage at pipe connections and valves.

O-rings offer several advantages, such as excellent wear resistance, chemical resistance, and the ability to function over a wide temperature range. Material selection is a crucial factor in meeting the specific requirements of a given application.

In conclusion, O-rings can be used to address a wide range of technical challenges, and they are indispensable in various industries for sealing and insulation purposes. It is essential to choose the appropriate material and size for the specific application to ensure reliable and efficient operation.

COATED and ENCAPSULATED O-RINGS

Coated O-rings are sealing elements equipped with special coatings to enhance their sealing and insulating properties. Here are some examples of coatings and their properties:

PTFE (Polytetrafluoroethylene) Coating

Properties: Excellent low-friction characteristics, outstanding chemical resistance, high-temperature tolerance.

Example Application: Hydraulic systems handling aggressive fluids.

Silicone Coating

Properties: Excellent flexibility, low wear, good temperature resistance.

Example Application: Food industry applications where hygiene and sealing are critical.

Peroxide Coating

Properties: Good chemical resistance, suitability for sterilization.

Example Application: Medical devices and pharmaceuticals in sterile environments.

FEP (Fluorinated Ethylene Propylene) Encapsulating

It is important to distinguish that in this case we are not talking about a coating produced by layer formation. The O-ring gets a FEP tube. cover. Properties: Excellent non-adhesive characteristics, high-temperature resistance, good electrical properties.

Example Application: Chemical industry applications where exposure to aggressive chemicals is a concern.

Molykote Coating

Properties: Excellent lubrication, low friction, wear resistance.

Example Application: Machinery manufacturing and automotive industry, where minimizing friction is important.

These coatings address various environmental and application requirements, improving the performance of O-rings in specific tasks. It's essential to select the appropriate coating and O-ring material for the best results in your application.

TECHNICAL GUIDES

The KTT tolerance table helps You in size selection

Material selection guide

Introduction of elastomers

KTT Sealing Technologies is currently the only manufacturer of sealing elements in Hungary that offers a wide range of sizes for all types of oil seals made of all widely used elastomer materials.

Our main activities are the production of oil seals as well as, the wholesale and retail sale of oil seals, O-rings, hydraulic seals, mechanical and technical assembly goods.

Contacts

KTT Kubinszky Sealing Technologies Ltd.9400 HUNGARY, Sopron, Besenyő str. 24/B.

Local Tax number: 11462390-2-08

EC VAT Number: HU11462390

Phone: +36 99 / click

E-mail: click

Monday–Friday: 9.00–16.00

Inventory information

The stock information on the webshop is real and constantly updated. We regularly expand our range based on customer demand.

If you are looking for special rubber products, contact us – KTT is your professional partner in sealing technology.

The KTT Kubinszky Sealing Technologies Ltd

is part of the Axel Johnson International Group.

Our references

BorgWarner, Bosch, Festo, Grundfos, Caterpillar, KUKA Robotics, Electrolux

We use cookies to personalize content and ads, provide social functions, and analyze our website traffic. We also share information about your website usage with our social media, advertising and analytics partners, who may combine the information with other information you have provided to them or collected from other services you use.