Most of the shaft seals we produce are first installed (OEM), but unfortunately we regularly find that even here the installation conditions are still not satisfactory. Our experience is even worse when it comes to replacement parts, although these shaft seals will have to stand up to even more demanding conditions. Therefore, we will briefly summarise what is required by the EU DIN 3760 standard and practice.

Choose the right material!

The first step in choosing the right radial shaft seal is the choice of material.

NBR can be used up to 100°C, but not permanently. See: KTT NBR radial shaft seals.

FKM can be used up to 200°C, but it is good to know that the rotating shaft near the sealing edge will increase the actual temperature by 10-30°C depending on the radial clamping force, speed, coefficient of friction and heat dissipation conditions. See: KTT FKM radial shaft seals.

FKM, as the "rubber version" of PTFE, is the elastomer with the lowest coefficient of friction.

NBR is good for engine oils and motor oils, but for petrol, FKM is the material of choice, which is the most chemical resistant rubber. Silicone can be used up to 180°C and is flexible at -50°C, but is no longer recommended for diesel oil.

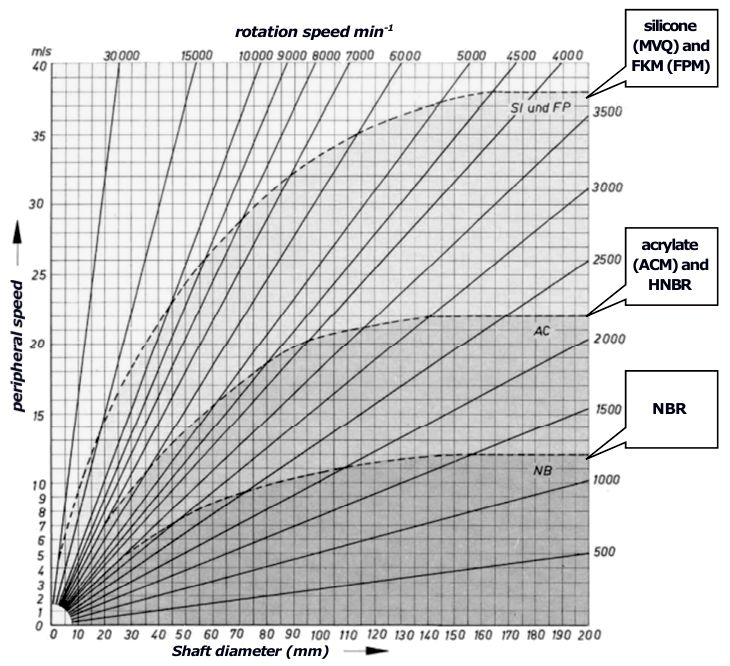

Use the nomogram for rotation speed–shaft diameter

Overstressed in the heat load, the built-up sym ring is hard at the edges, often cracked radially. In such cases, switch to a higher material grade.

If the heat and chemical resistance of FKM is not sufficient, PTFE with metal housing is the right solution. See: type B2PT.

When fitting, it is important that both the shaft to be sealed and the bore of the sealing ring are provided with a suitable conical groove and radius. For installation, use a tool that presses the seal in as close as possible to the outside diameter. Ensure that the sealing edge is perfectly perpendicular to the shaft.

Don’t insist on the same height as the original on a replacement part, it is unprofessional to "run" the seal on an imperfectly rebuilt axle in the same place where its previous part damaged it. Perfectly reconditioned shafts are rare, because new ones do not always meet the standard: they must have a roughness depth of 4 microns and a hardness of 55 HRC at 0.3 mm depth. In addition to the obligatory rigidity already mentioned at the time of installation, three geometric factors can impair the perfection of the seal:

- The centre line of the bore of the shaft seal and the shaft must not diverge. The "culprit" for this is the edge – that is worn on one side when the axle is removed.

- Only very small shaft ovality are allowed.

- A shaft run-out of more than 0,1 mm even at medium speeds can only be sealed by means of a back pressure groove (on other names: leading pattern or drall).

The shaft seal must not be subjected to a pressure of more than 0.5 bar. This must be kept to even if the sealing lip does not turn out, as high pressures cause wear and heat build-up, and even distort the life of the sealing lip in the wrong geometry. It follows that FKM tolerates small overpressures better. We offer Simrit BABSL models, these are pressure resistant up to 10 bar, but wear faster at higher speeds. See: BABSL products.

Recommenden elastometers for the radial shaft seals depending on the rotation speed and shaft diameter

EU DIN 3760 requirements for the overlapping of the outer diameter of shaft seals

|

outside diameter (mm) | required overlap | allowed deviation from circularity |

| to 50 | +0,30 +0,15 | 0,25 |

| over 50 to 80 | +0,35 +0,20 | 0,35 |

| over 80 to 120 | +0,35 +0,20 | 0,50 |

| over 120 to 180 | +0,45 +0,25 | 0,65 |

| over 180 to 300 | +0,45 +0,25 | 0,8 |

| over 300 to 500 | +0,55 +0,30 | 1,0 |

Technical data sheet of the KTT's own manufactured radial shaft seals (pdf)