In addition to heat transfer, press vulcanisation and injection moulding technologies, KTT is also involved in design. See our technologies!

Product development, tool design

KTT effectively supports its customers in the design process. We use our expertise and experience to provide solutions or suggestions that improve product functionality and quality while reducing tooling and manufacturing costs.

Toolmaking

Our in-house tooling not only keeps the cost of manufacturing down, but also ensures that our customers receive their first samples in the shortest possible time. Once sampling starts, tool optimization is also significantly faster than with an external toolmaker. In practice, we can offer a tool ready for series production within a few weeks.

Heat transfer vulcanisation

The heat transfer process is typically used to produce smaller batches. For customer-specific products requiring metal-rubber bonding, 1-4 cavity moulds can be used to produce economically with high throughput and speed, even if the required quantities do not exceed a few hundred or a few thousand pieces.

Compression molding

Compression molding is one of the most common manufacturing processes for rubber products. It involves placing pre-processed, extruded rubber material into a mould and compressing it to give the rubber the desired shape. At the same time, excess air is extracted from the mould to help ensure proper distribution of the material in the mould. Since several different inserts can be placed on the heating plates at the same time, this method is cost-effective and at the same time ensures excellent accuracy, which is also required by the automotive industry.

Injection molding

Rubber injection molding is a versatile manufacturing process for producing high-quality rubber parts. It involves injecting molten rubber into a mold cavity under pressure, allowing for complex shapes and precision. This method ensures consistency, durability, and excellent surface finish. Rubber injection molding finds applications in various industries, including automotive, medical, and consumer goods.

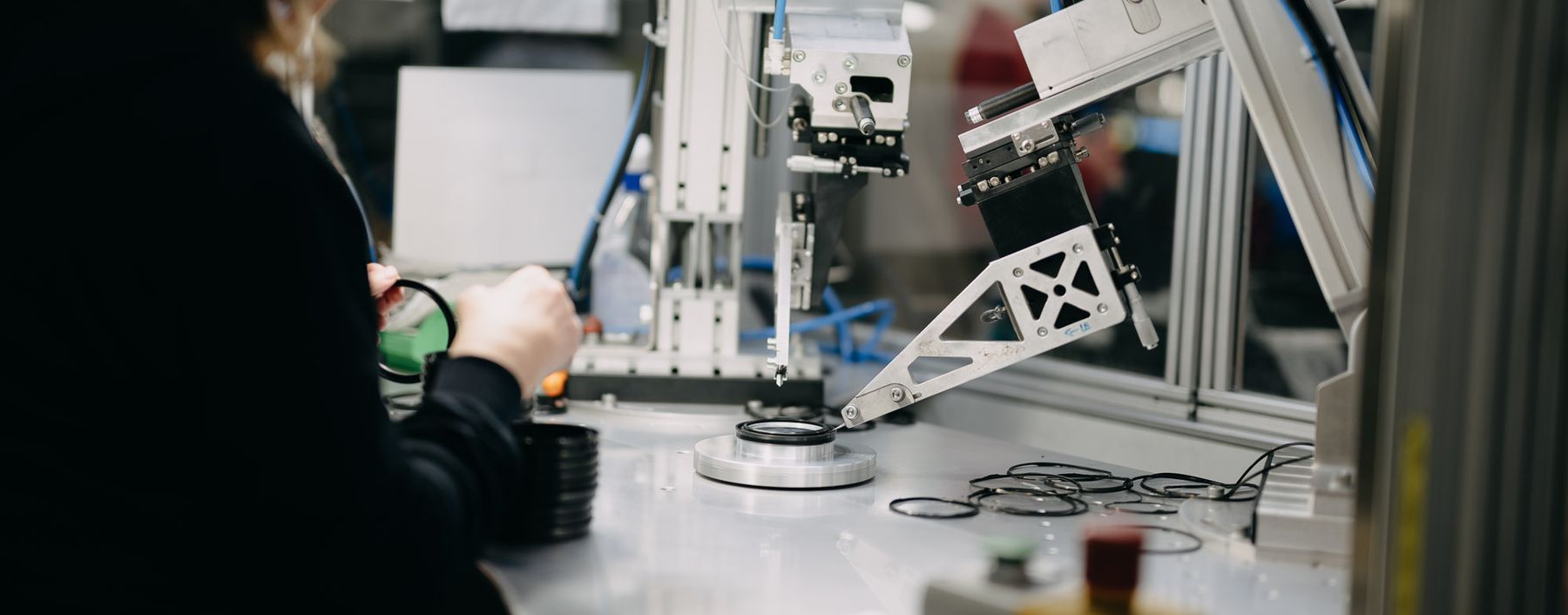

Precision finishing

Finishing can consist of several steps. On the one hand, the precision forming of the sealing edges of the vulcanized products is carried out. In addition, the products are subjected to a tempering process appropriate to the type of material, during which the final chemical structure of the material is formed and this ensures the best properties for subsequent use.

Degreasing, LABS-free cleaning

LABS-free means that a product or substance is free from residual solvents based on aromatics (aromatic solvent residues). LABS stands for “Lösemittel Aromaten Benzol und Schwefel.” This term is often used in relation to rubber and plastic materials to ensure that they do not contain harmful solvent residues that could potentially be hazardous to health. Being LABS-free is a quality characteristic that ensures the safety and health compatibility of a product.

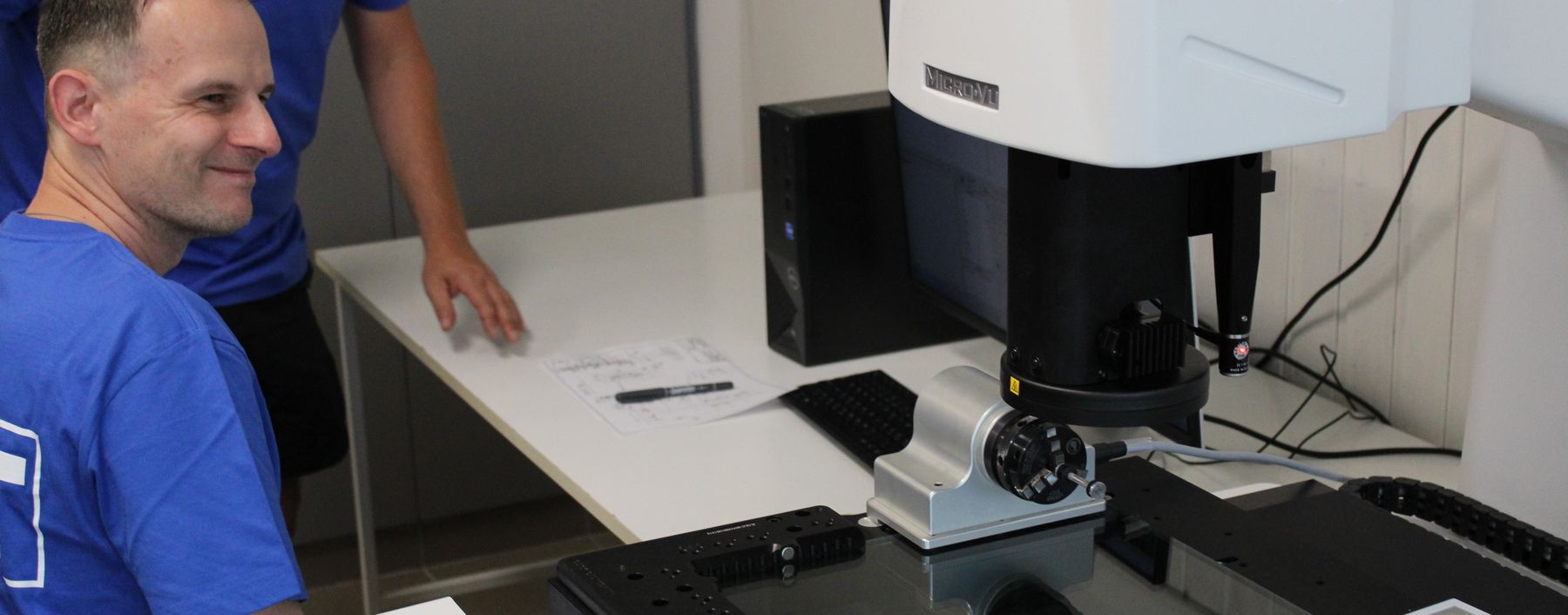

Measuring and control techniques

We use a range of procedures and equipment to check the quality of the products we manufacture. One of our most important pieces of equipment is a modern 3D optical and tactile measuring machine with a 400x400 mm slide table, which enables the necessary measurements to be made much more accurately and quickly than in previous solutions.

Any other questions or comments about the technologies? Feel free to contact us, we are at your service!